Information for Architects

Information for Architects, Designers, Healthcare Providers and Building Contractors looking to incorporate Visitor facilities into Ward Refurbishment and new-build Hospital and Hospice projects, to enable patients to have someone they know and trust stay with them overnight.

Healthcare Project Planning

We work closely with architects and associated professionals, to ensure that our beds integrate seamlessly into Hospital and Hospice projects.

Hospital Visitor Beds are the UK’s longest established and leading specialist designers and suppliers of World Class foldaway Visitor wall beds and guest beds for Hospitals and Hospices.

Our products are the only space and cost saving Visitor beds specifically engineered to withstand daily, long term, heavy duty use in Hospitals and Hospices, the only ones to come with a 10 year bedframe guarantee and the only award winning ones.

Our products comply with all current Infection Control, Health & Safety, Manual Handling and Flame Retardancy requirements and offer a host of additional benefits for visitors, patients and Ward staff, including safety, comfort, convenience, ease-of-use and significant time and cost savings.

Because we make our beds for each project, we can be flexible about special customer requests and design modifications.

Services for Architects

- Free in house consultancy to discuss projects and/or special requirements

- Drawings for integration into your design work

- Design meeting attendance, plan reviews and on site measurements

Two World Class Visitor Bed Ranges

We offer a choice of 2 distinct award winning Visitor bed ranges:-

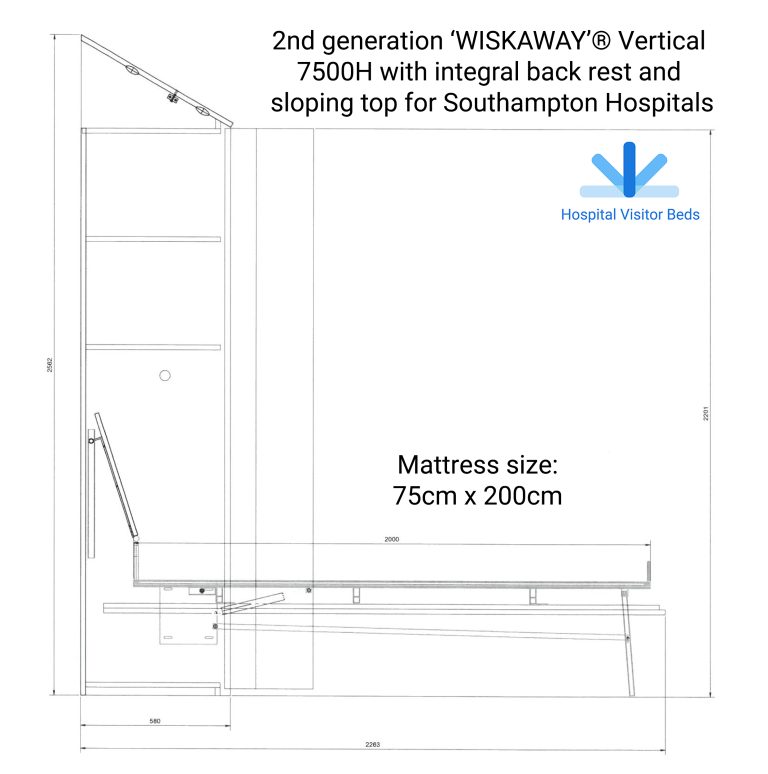

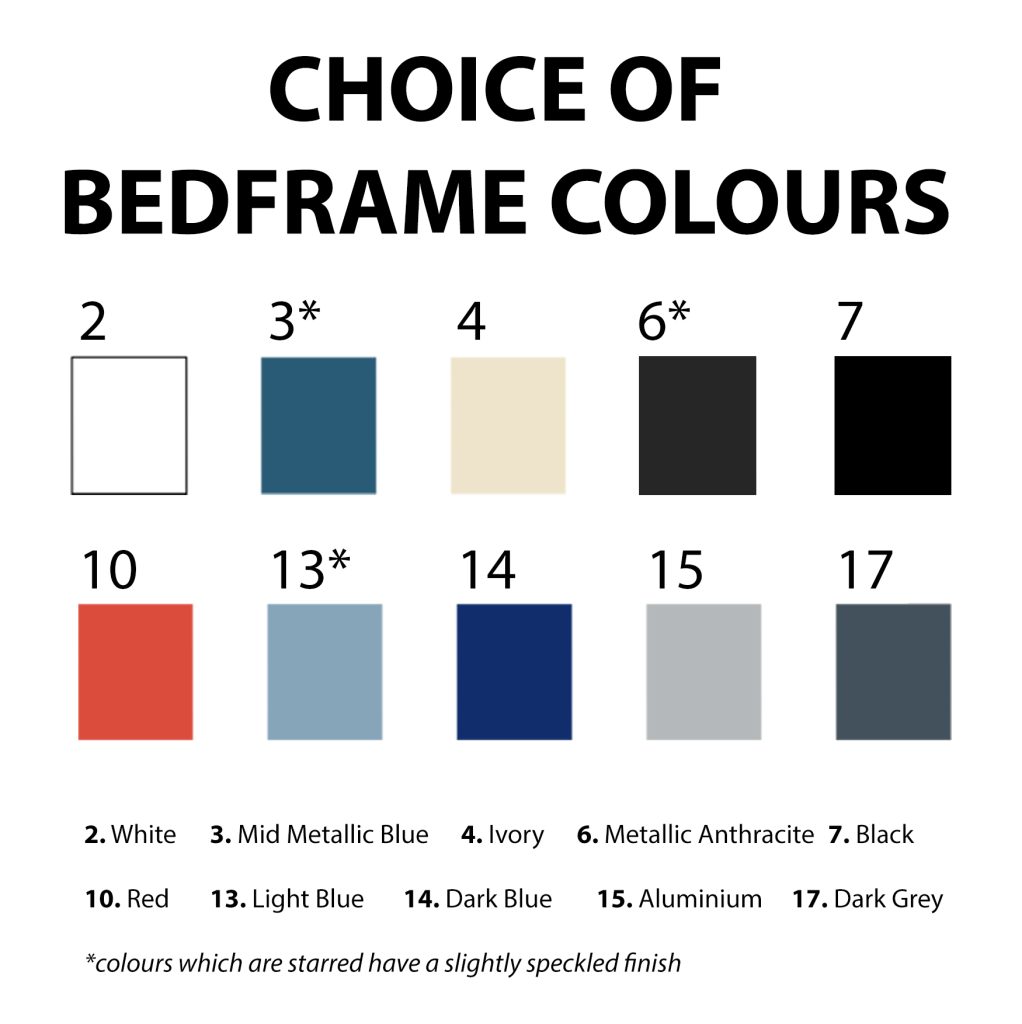

1) Our wall–fixed, all-steel ‘Horizontal’ and ‘Vertical’ ‘WISKAWAY’® and ‘NEAT-A-WARD’® Wallbeds, which come in single, double and made-to-measure sizes and in a wide choice of bedframe colours and finishes for the wipe-clean housings and optional matching furniture and can be pivoted away complete with all the bedding, including the pillows (in just seconds in an emergency).

Our ‘NEAT-A-WARD’® Patient Wallbed has been specially designed for use on Midwife-Led Birthing Units with no hospital bed in the room. The ‘NEAT-A-WARD’® is normally concealed in an architect designed wall unit, as illustrated below.

2) Our versatile mobile, single and double ‘GLIDEAWAY’® Visitor Guestbeds, for applications where wall beds are not suitable, for instance existing situations with insufficient uncluttered wall space. The ‘GLIDEAWAY’® can be made up wherever and whenever required and is the next best alternative to our ‘WISKAWAY’® Visitor Wallbeds, in terms of comfort, convenience, ease of use and resilience and is equally suited to both short term and longer term use.

What’s our secret?

We pioneered the use of wall beds in Hospitals and Hospices in the UK and have an unmatched 40 year-plus track record. Our all-steel wall bed frames have been specifically designed for the Hospital and Hospice Visitor bed application, are all fully compliant, are available in made-to-measure as well as standard sizes, will easily outlast anything else on the market (see the Addenbrookes and Bristol Children’s Hospital Case Studies 1 & 2) and are award winning.

They are additionally supported by a full after-sales service and offer unbeatable value for money, even paying for themselves during the course of their impressively long service lives.

Why the side flaps?

Architects often ask us for a wall bed with a one-piece front panel and we can make one (our ‘Vertical’ model 8000H – see below), but it has several disadvantages, compared to the ‘Vertical’ ‘WISKAWAY’® 7500H Wallbeds featured on this website, as the front legs on beds with a one piece front panel either have to be manually rotated round the front edge of the front panel, or have to be pushed forwards and twisted, mechanically, through 90 degrees, as the bed is lowered, which involves a more complicated mechanism.

In both cases, this results in the front legs protruding beyond the front panel, when the bed is deployed and constituting a trip hazard.

The side flaps on our ‘WISKAWAY’ 7500H Wallbed housings allow us to use a strong simple bar to automate the front legs, which are located safely out of the way, underneath the bedframe, when deployed. An additional advantage of the side flaps is that they keep the bed safely closed when not in use. A third major advantage is that the bedding does not have to be carefully tucked in all around, before the bed is pivoted away, as it does with a one-piece front panel. This saves time and, over the long service life of the beds, results in significant reductions in operating costs.

Easy to Handle, Place and Install

Our ‘WISKAWAY’ Visitor Wallbeds are designed to be easy to transport, place and install and arrive, well packaged and fully assembled, as a ‘box’ with the bed inside, which can be easily transported on a flat trolley and placed, ready to be scribed to the coved floor and fixed to the wall behind.

Our ‘Vertical’ ‘WISKAWAY’® Wallbeds are fixed by means of special wall brackets (provided), located above the tops of the housings and the wall backets (provided) for our ‘Horizontal’ wall beds are located underneath the top panel. Matching furniture, such as lockers and top boxes, is similarly delivered assembled and ready to fix.

Our wall beds and matching furniture can easily be unfixed, however and re-located -(see Royal Manchester Children’s Hospital Case Study 7), or temporarily moved, to allow for a new floor to be laid, for instance -(see Addenbrookes Hospital Case Study 1).

Design Flexibility for Architects

Because we make our beds specifically for each project, we can adapt our designs to suit your project’s requirements.

We offer:

- Made to measure sizes and bespoke variants – see below

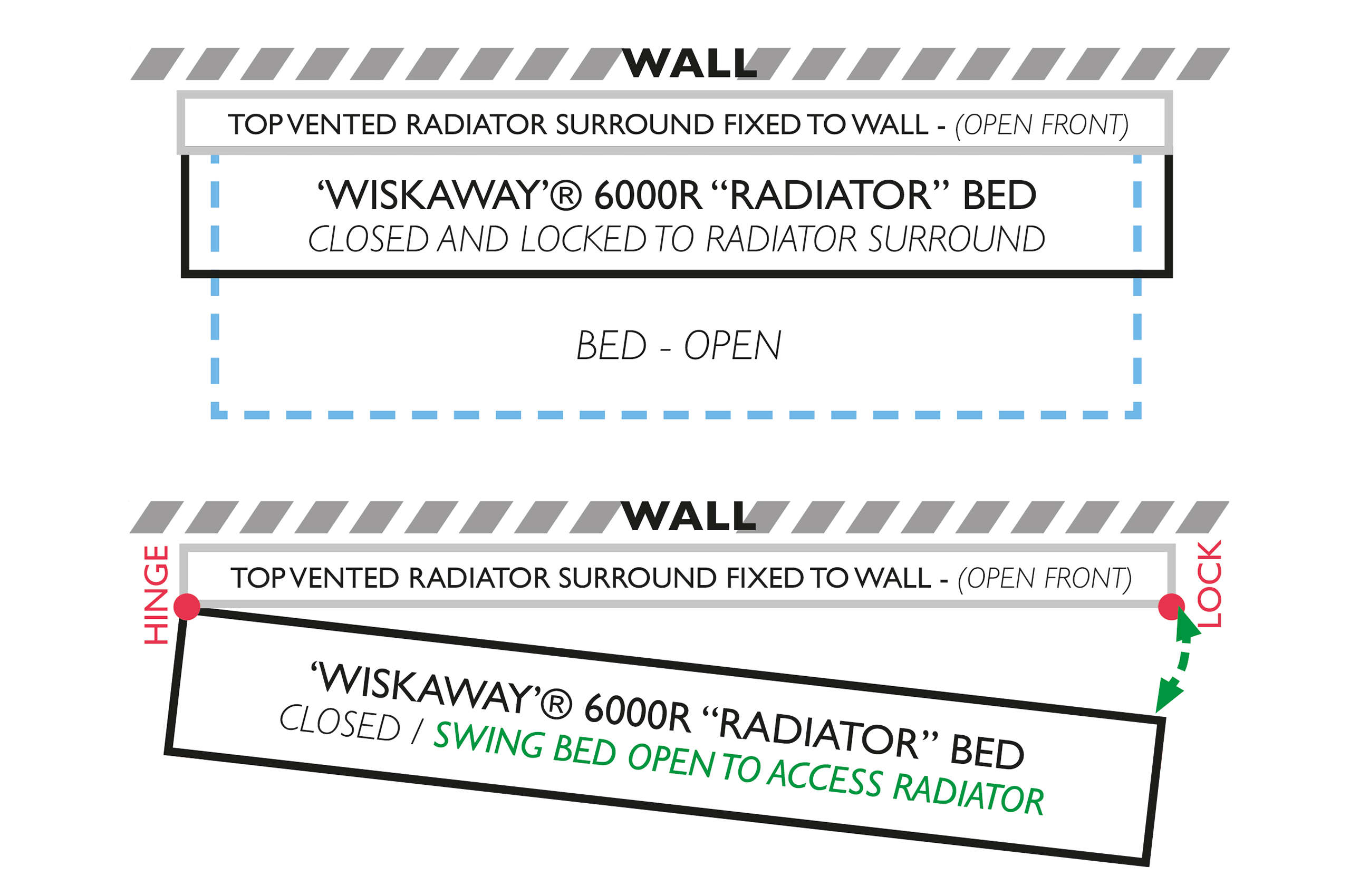

- Solutions for awkward spaces (around pillars, in front of radiators) – see below

- Extra high options to suit specific clinical needs – see below

- 10 standard powder coated bedframe colours (see below), with most RAL colours available, on request, for larger orders

- A wide selection of ‘wood effect’ and plain finishes for our wall bed housings and matching furniture in wipe clean MFC or plastic laminate – see below

- Complementary fitted furniture (e.g. wardrobes, lockers, top boxes, worktops, etc.) in a wide range of finishes – see below

Carbon Footprint

Every effort goes into producing products with the lowest possible carbon footprint and, over the very long service lives of our products, they have a lower carbon footprint, compared to ‘similar‘ products, when evaluated over the same period.

Our Hospital Visitor beds Pay For Themselves By Saving Money In 4 Ways

- By accommodating visitors on the Ward, there is no need for separate visitor rooms.

- Ease of handling leads to lower staff workload and reduced operating costs.

- Reduced stress all round results in faster patient recovery, shorter inpatient stays and significant cost savings.

- Ultra-long service lives maximise value for money and can result in very substantial cost savings.

Post Delivery Services for End-Users

- Installation service to unload, place and fit our Visitor wall beds, we can also arrange to re-locate these. Our experienced fitters are comfortable working on live wards, refurbishments, or new-build projects.

- Full after-sales service, including optional periodic servicing – (we recommend just once every 5 years).

Our Extensive Client History

Our beds are used by major Hospitals, Children’s Hospitals and Hospices across the UK. For typical real life examples, please see the Case Studies section and also the sample list below of just some of our many repeat Hospital and Hospice customers.

Some of our long-standing repeat customers